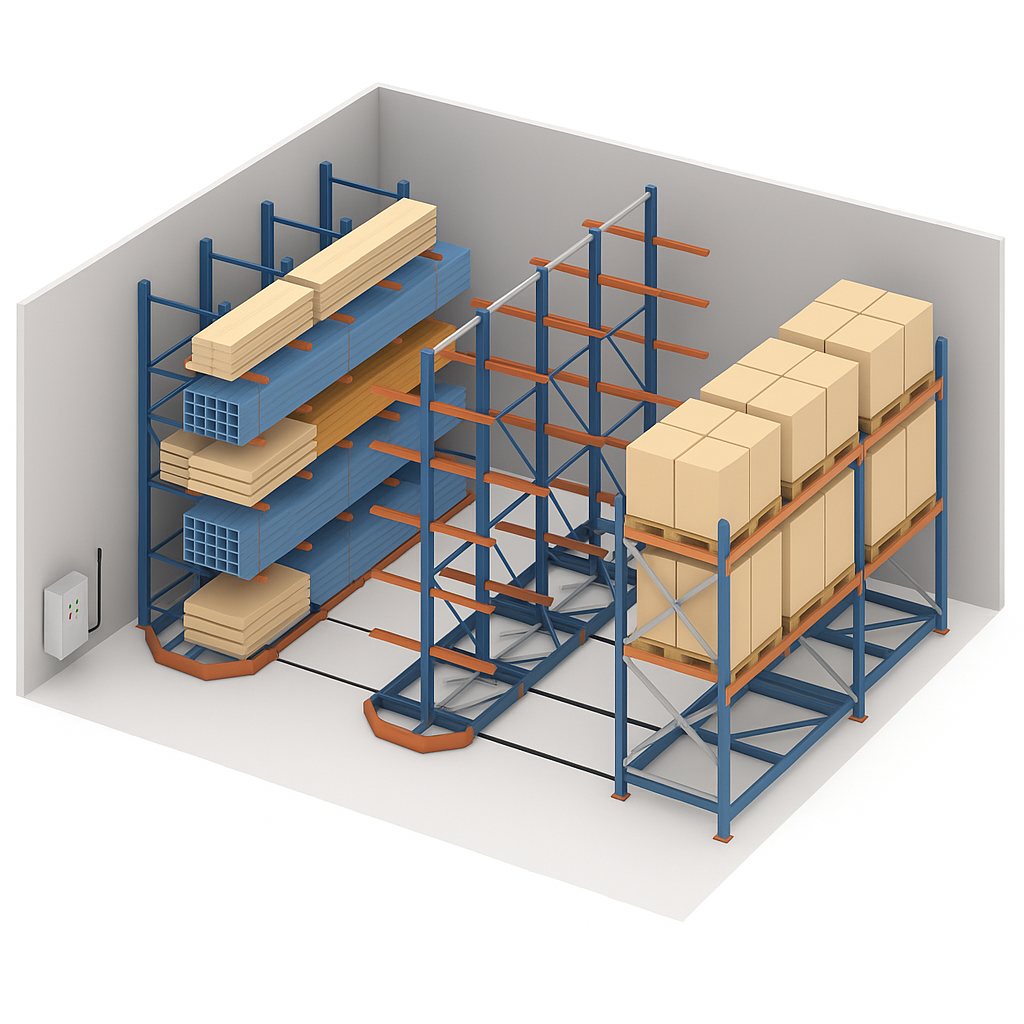

Pallet Racking Systems

Your Complete Resource for Pallet Racking and Warehouse Storage in Sinking Spring, PA

PALLET RACKING OVERVIEW

Warehouses and distribution centers rely heavily on pallet storage systems for their palletized goods. These industrial shelving layouts are meticulously engineered.

Pallet racking is a foundational material handling storage system for single items or palletized materials in multi-level horizontal rows. These storage racks use vertical uprights and horizontal load beams to support stored loads.

Accessed by carts or lift trucks, selective pallet racking offers direct access or compact storage. It's a key warehouse organization tool for product pallets. All types of industrial shelving allow multi-level storage, and forklift trucks are usually needed for loading. Since the Second Industrial Revolution, these storage solutions are common in warehouses, manufacturing, retail, and distribution.

Palletized storage increases storage density, with costs varying accordingly. Industrial shelving is a popular and adaptable storage method for large items or palletized loads.

Looking for used pallet racks? Discover cost-effective solutions for your warehouse.

Key Features of Pallet Rack Systems

Pallet rack systems are essential components of modern warehouse infrastructure. Designed to maximize vertical space and improve operational flow, these systems are engineered with a variety of smart features to ensure efficiency, durability, and adaptability for different industries.

Adjustable Beam Levels

Most pallet rack systems feature adjustable beams, allowing flexibility in storing items of various heights and sizes.

Heavy-Duty Uprights

Constructed from reinforced steel, the vertical uprights provide strong load-bearing capacity and long-term stability.

Safety Locking Pins

Safety pins are used to secure beams in place and prevent accidental dislodging due to vibrations or impacts.

Powder-Coated Finish

A high-quality powder coating enhances corrosion resistance and prolongs the lifespan of the rack components.

Custom Configurations

Racking systems can be tailored with accessories like wire decks, row spacers, and column protectors for unique needs.

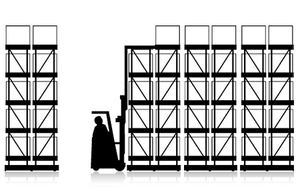

Forklift Accessibility

Designed with forklift-friendly dimensions and clearance, ensuring smooth loading and unloading operations.

💡 Pro Tip: Before choosing a pallet rack system, evaluate your inventory weight distribution, SKU variety, and forklift turning radius. Proper alignment of racking specs with workflow minimizes risks and boosts productivity.

Types of Pallet Racking Systems

Understanding the different types of pallet racking systems available is crucial for optimizing your warehouse storage. Each system offers unique advantages depending on your inventory, space constraints, and operational needs. Explore the various options below to find the perfect solution for your business.

Selective Pallet Racks

The most popular and versatile option, selective pallet racks provide immediate access to every pallet. Ideal for warehouses needing quick, frequent access to multiple SKUs.

Drive-In Pallet Racks

Offering high-density storage, drive-in pallet racks allow forklifts to drive directly into the racks. Best for storing large quantities of similar products, especially perishable goods (LIFO).

Push-Back Pallet Racks

Pallets are loaded/unloaded from the same aisle using inclined rails and carts. Best for medium-density storage, optimizing limited space while maintaining good selectivity.

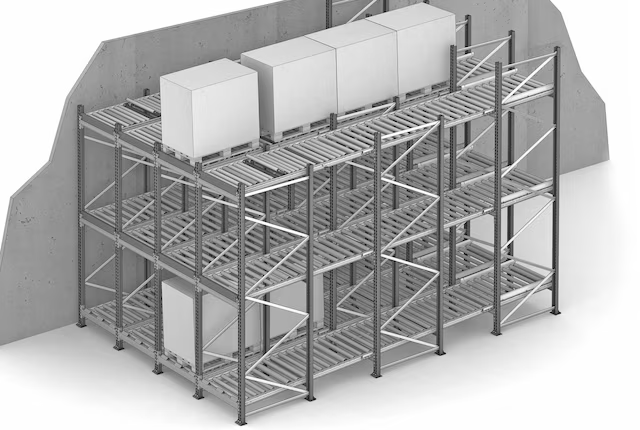

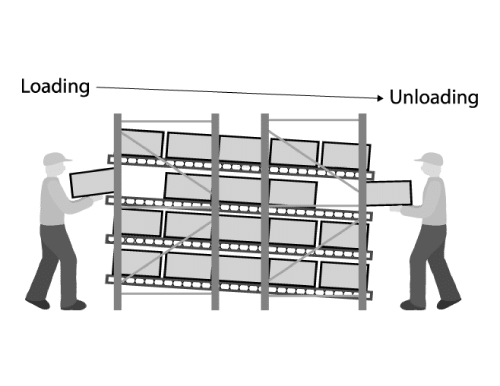

Pallet Flow Racks

Pallets move forward automatically via gravity rollers. Best for high-density, FIFO inventory rotation—ideal for perishables or expiry-sensitive items.

Cantilever Racks

Open-front design with arms extending from vertical columns. Best for storing long, bulky, or oddly-shaped items (pipes, lumber, furniture).

Double Deep Pallet Racks

Similar to selective but stores pallets two-deep. Best for increased density over selective racks, suitable for moderate variety SKUs.

Mobile Pallet Racks

Racks mounted on movable bases on tracks. Best for maximizing storage density while maintaining selectivity, ideal for limited floor spaces.

Narrow Aisle / VNA Racks

Selective racks placed closer together, requiring specialized forklifts. Best for high-density storage environments requiring precision handling equipment.

Carton Flow Racks

Gravity-fed shelving systems for boxes/cartons. Best for high-volume picking operations, FIFO systems, often used in e-commerce fulfillment.

Key Benefits of Pallet Racking Systems

Pallet rack systems are a critical part of efficient warehouse layout and inventory handling. They help streamline storage, reduce damage, improve worker productivity, and make the best use of your warehouse's vertical space. Below are the key benefits of installing pallet racking systems in your facility.

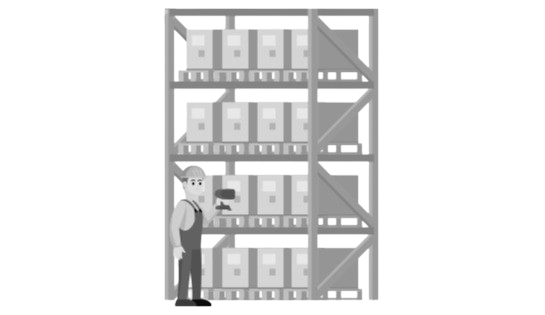

Improved Inventory Visibility

Track and manage inventory with ease using clearly visible rack levels and organized layout.

Faster Order Picking

Efficient rack layout enables rapid SKU identification and streamlined order fulfillment.

Maximized Space Utilization

Make use of vertical space to reduce warehouse footprint and increase pallet positions.

Reduced Product Damage

Organized rack storage minimizes shifting and handling issues, preserving product integrity.

Improved Operational Efficiency

Reduces travel time for forklifts and simplifies movement throughout the warehouse.

Scalable Storage Solution

Easily expandable and reconfigurable to meet future warehouse growth and changes.

🏢 Industries Utilizing Pallet Racking

Pallet racking systems are a cornerstone of industrial racking solutions, serving a wide variety of sectors that demand efficient, scalable, and durable warehouse pallet racking. Below we explore some of the top industries where these systems play a critical role in daily operations.

E-commerce & 3PL Fulfillment

Pallet racking systems are essential in high-velocity e-commerce warehouses and third-party logistics centers (3PLs) where rapid picking, high SKU counts, and real-time inventory visibility are critical. These systems support fast-moving operations, reduce downtime, and allow scalable growth in fulfillment zones handling thousands of orders daily.

Postal & Government Logistics

Large-scale logistics operations, including government postal services, require exceptionally durable and standardized storage. Our heavy-duty systems are engineered to meet these demands, making them suitable as USP pallet racking solutions for mail sorting facilities and large distribution hubs where reliability and high volume throughput are essential.

Food & Beverage / Cold Storage

Cold storage facilities and food-grade warehouses rely on industrial pallet racking to maintain hygiene standards, temperature zoning, and optimized FIFO flow. Pallet racks allow dense storage of packaged foods, beverages, and perishables, while improving access, load control, and compliance with food safety regulations.

Retail Distribution Centers

Retailers require organized pallet racking to streamline restocking, manage large SKU volumes, and reduce floor clutter. Distribution hubs benefit from selective and double-deep pallet racks to speed up replenishment cycles, improve stock rotation, and maintain warehouse efficiency across multiple product categories.

Automotive Industry

Automotive warehouses and assembly units use heavy-duty pallet racking to handle bulky components like engines, tires, body panels, and tools. Racking systems support sequential manufacturing workflows, prevent damage to sensitive parts, and enable just-in-time inventory replenishment for production lines.

Manufacturing & Industrial Units

In large-scale manufacturing, pallet racks are essential for staging raw materials, work-in-progress items, and finished goods. Configurable systems like cantilever and selective racks help manage production buffers, optimize factory floor space, and improve supply chain continuity in industrial workflows.

Pharmaceutical Warehousing

Pharmaceutical companies require specialized warehouse pallet racking systems for clean-room storage, batch-controlled pharmaceuticals, and temperature-sensitive drugs. Racking helps ensure traceability, improves SKU separation, and meets stringent regulatory compliance in biotech and healthcare supply chains.

🟢 How to Choose the Right Pallet Rack System

Choosing the right pallet rack system is essential for optimizing storage, improving accessibility, and ensuring long-term warehouse efficiency. Whether you're dealing with high SKU turnover, heavy loads, or limited space, the right choice can dramatically improve operations. Below are key factors to help you make the best decision for your warehouse.

Load Size & Weight

Evaluate the maximum weight and dimensions of your pallets. The best pallet racking system must support your inventory load without compromising safety or durability.

Inventory Flow (FIFO / LIFO)

Understand your product rotation cycle thoroughly. First-In, First-Out (FIFO) systems are typically best for perishable goods, while Last-In, First-Out (LIFO) is often ideal for bulk.

Ceiling Height & Floor Space

Match your racking system to available vertical clearance and floor layout. Pallet racking maximizes warehouse cubic footage when planned properly.

Type of Goods & SKUs

High-SKU warehouses require selective or narrow-aisle racks. Bulky or long items may need cantilever racks for ideal storage efficiency.

Forklift Compatibility

Consider turning radius, reach height, and aisle width. Not all racking systems support all forklift types—especially VNA or deep-reach trucks.

Budget & Future Scalability

Don’t just think short-term. Choose a pallet racking solution that grows with your business and allows easy modification or expansion.

Frequently Asked Questions (FAQs)

What is a pallet racking system?

A pallet racking system is a warehouse storage solution that stores palletized goods in horizontal rows across multiple levels. It allows for efficient space utilization and is accessed by forklifts for easy loading and unloading.

What are the most common types of pallet racking in the U.S.?

In the U.S., the most common pallet racking systems are Selective Pallet Racks, Drive-In Racks, Push-Back Racks, Cantilever Racks, and Pallet Flow Racks. Each type supports different inventory flow and storage density needs.

How do I choose the right pallet rack for my warehouse?

Choosing the right pallet rack depends on factors like SKU variety, inventory turnover rate, available floor space, and forklift type. Our experts can help design a custom layout based on your storage goals.

Are pallet racks compliant with OSHA and ANSI standards?

Yes, all pallet racks we provide are designed in compliance with ANSI MH16.1 standards and OSHA guidelines to ensure safe structural performance and worker safety.

Can you install pallet racks anywhere in the U.S.?

Yes. United Rack Solutions provides nationwide delivery, layout design, and installation services across the United States, including permit assistance and code-compliant configurations.

How much weight can pallet racking systems support?

Load capacity depends on the beam size and rack type but can range from 2,000 lbs to 6,000+ lbs per level. We'll help calculate the right configuration based on your inventory needs.

Do you offer used pallet racking systems?

Absolutely. We stock high-quality used pallet racks that meet safety standards and are ideal for budget-conscious warehouses across the U.S.

Can pallet racks be reconfigured or expanded later?

Yes, most pallet racking systems are modular and can be reconfigured, expanded, or relocated as your warehouse needs grow or change.

Comparison of Pallet Racking Systems

| Type | Icon | Storage Density | Selectivity | Best Use Case | Forklift Access | FIFO / LIFO |

|---|---|---|---|---|---|---|

| Selective Pallet Racks |  |

Low | High | General warehouses with various SKUs | Direct aisle access | FIFO |

| Drive-In Pallet Racks |  |

Very High | Low | Bulk storage of similar items | Drive-in access | LIFO |

| Push-Back Pallet Racks |  |

High | Medium | Limited SKU storage, space optimization | Single-aisle access | LIFO |

| Pallet Flow Racks |  |

Very High | Medium | Perishables with rotation needs | Rear load / front pick | FIFO |

| Cantilever Racks |  |

Medium | High | Long/bulky items like pipes, lumber | Open front, easy side access | Manual/FIFO |

| Double Deep Pallet Racks |  |

Medium-High | Medium | Moderate SKU storage, improved density | Special reach trucks | LIFO |

| Mobile Pallet Racks |  |

Very High | High | Limited floor space with high SKU access | Movable racks on tracks | FIFO |

| Narrow Aisle / VNA Racks |  |

High | High | Space-saving with advanced equipment | Turret trucks or VNA forklifts | FIFO |

| Carton Flow Racks |  |

High | High | High-volume picking operations | Manual pick / gravity-fed | FIFO |