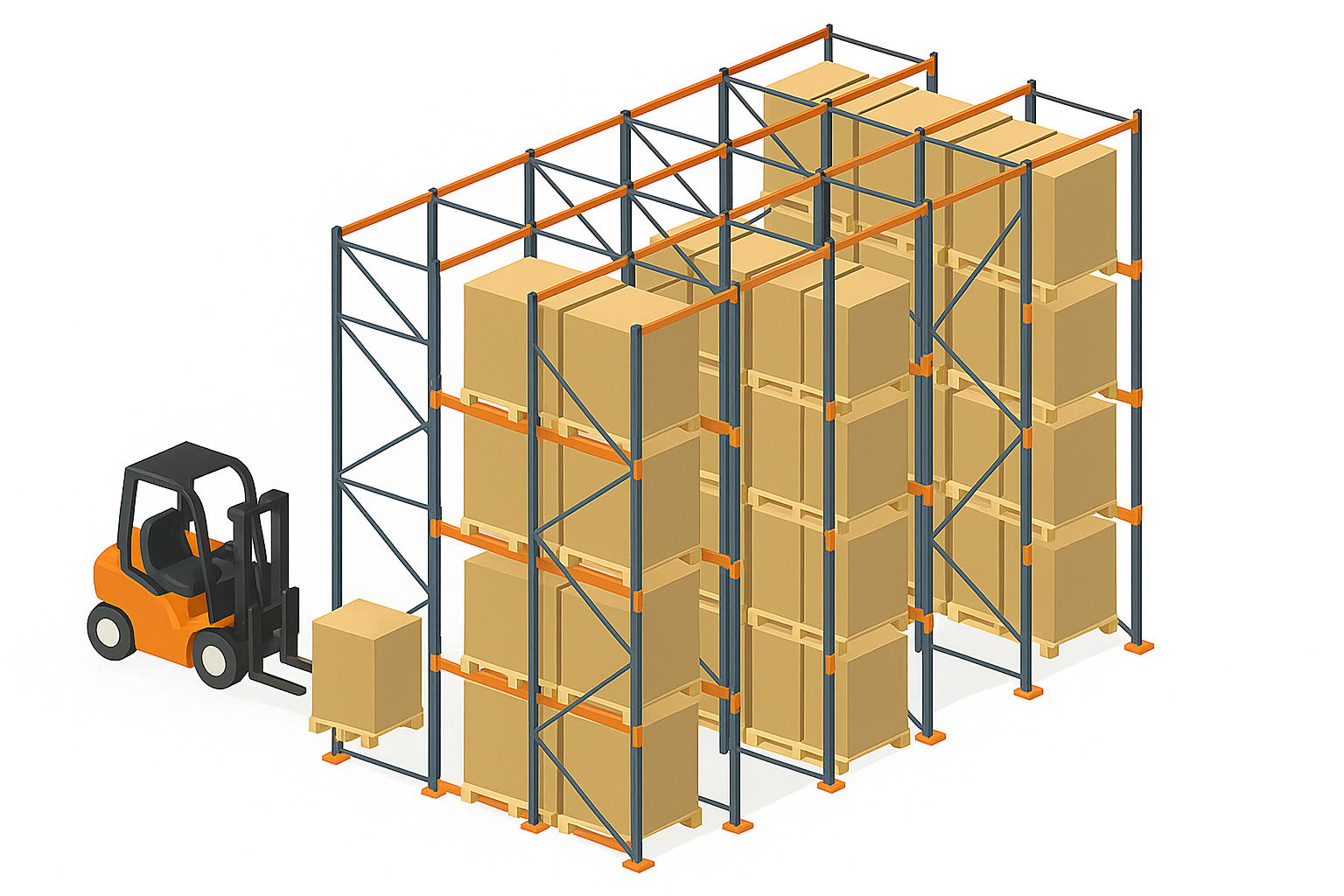

Drive-in Pallet Racking

Maximum Storage Density for Last-In, First-Out Operations

Drive-In Pallet Rack System Highlights

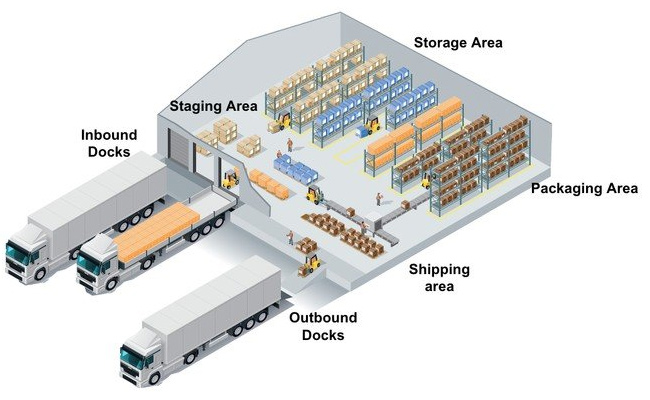

Drive-In Pallet Racks maximize storage density by allowing forklifts to drive directly into storage lanes, ideal for high-volume inventory with limited space. Perfect for FIFO or LIFO operations in warehouse design and layout, cold storage, food distribution, and bulk warehousing.

- High-density storage with minimal aisle space

- Supports both FIFO and LIFO inventory rotation

- Reduces warehouse footprint by up to 60% vs. selective racks

- Ideal for cold storage, beverages, and durable bulk goods

- Durable steel construction for heavy-duty pallet loads

Detailed Benefits and Advantages of Drive-In Pallet Racks

Drive-In pallet racks offer an excellent high-density storage solution for warehouses looking to optimize their available space. Their LIFO-based operation and compact design make them ideal for storing bulk goods with fewer SKUs and longer shelf lives. Let's explore the key advantages in greater detail.

High-Density Storage

Drive-In racks maximize warehouse space by reducing aisle requirements, allowing more product to be stored in the same area.

Space Optimization

The system reduces aisle space by 40–50%, allowing for better use of warehouse square footage.

Cost-Effective

Drive-in racking is an economical choice for bulk storage, reducing the need for multiple racking aisles and systems.

Improved Efficiency

With fewer aisles and streamlined access, Drive-In racks help reduce handling time and improve operational flow.

Structural Simplicity

Fewer components and open bays make installation simpler, while still offering strong load capacity and long-term use.

Reduced Product Damage

With fewer forklift maneuvers and enclosed lanes, product damage from mishandling or shifting is significantly minimized.

💡 Pro Tip: To ensure smooth operation in drive-in racks, always train forklift operators on bay entry angles and lane depth limits. Routine inspection of rails and backstops ensures safety and minimizes damage risks.

Components and Design of Drive-In Pallet Racks

Drive-In Pallet Rack systems are essential for high-density warehouse storage. They use vertical space efficiently, follow LIFO storage flow, and reduce aisle needs. Here's a breakdown of the key components that make them stable, efficient, and forklift-friendly.

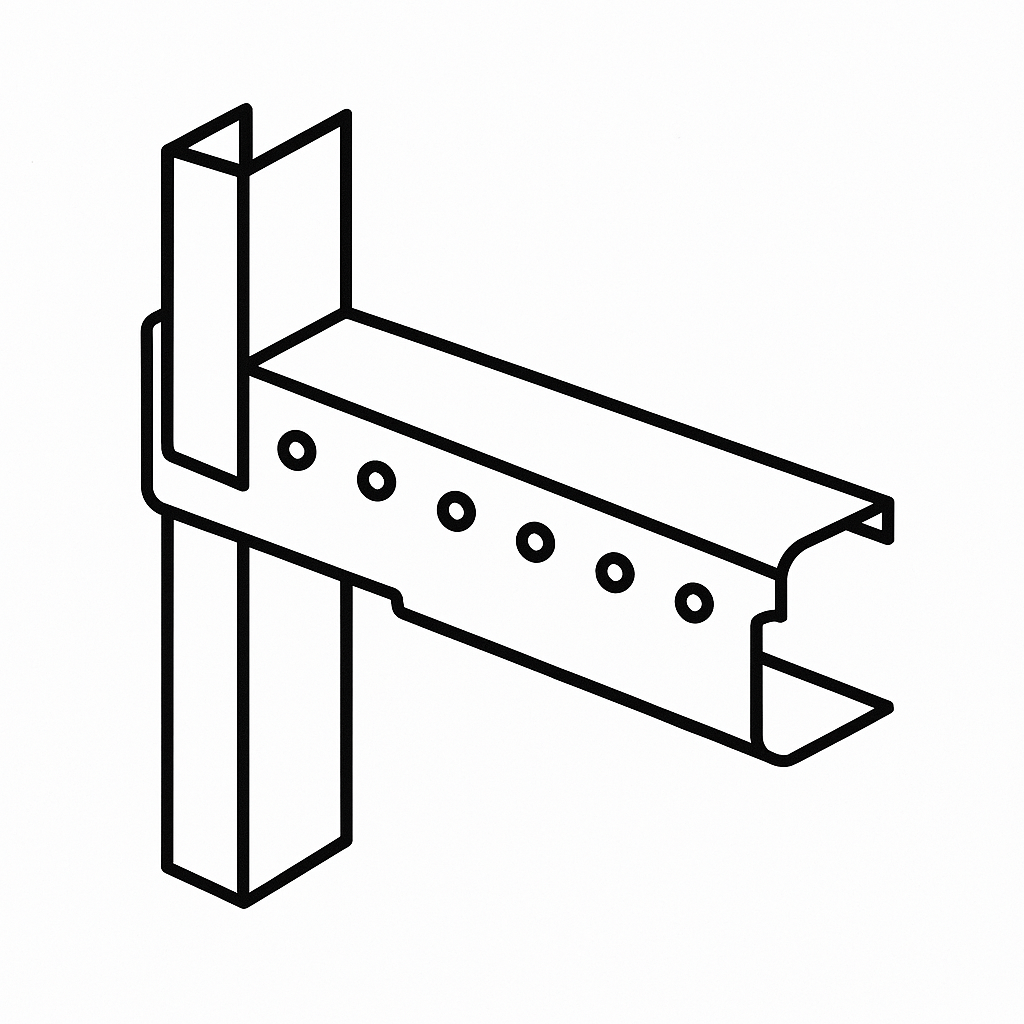

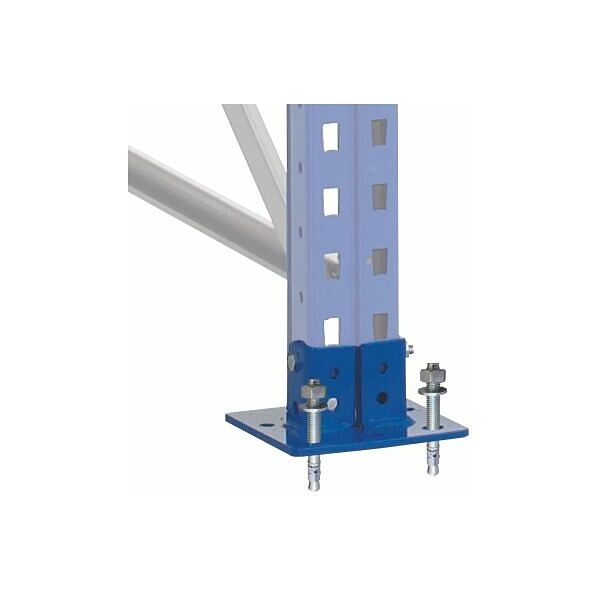

Upright Frames

The vertical steel columns that form the backbone of the rack system, bolted to the floor for solid load support.

Horizontal Beams

Strong crossbars connecting upright frames to enhance stability and prevent sway across the structure.

Pallet Rails

Heavy-duty tracks that run deep into the bays to directly support pallets and guide forklift placement.

Entry Guides

Robust floor-mounted guides that align forklifts for accurate pallet entry without damaging racks.

Top Ties

Cross connections across the tops of frames, improving rigidity and resistance against leaning.

Back Stops

Stop bars at the rear of bays to prevent pallets from being pushed off the end and maintain safety.

Applications and Industries for Drive-In Pallet Racks

Drive-In Pallet Rack systems are a versatile, high-density solution for low-SKU or high-volume inventory. Below are typical applications and the industries that benefit most.

Ideal for Specific Inventory Types

Drive-In racking excels at storing large runs of the same product (low SKU counts). With a Last-In, First-Out (LIFO) flow, the newest pallet is always at the pick-face. Perfect for:

- High-volume production runs of identical items

- Seasonal goods or products with predictable demand

- Buffer stock / reserve inventory

- Non-perishables or products with long shelf life

Common Industries Utilizing Drive-In Racking

Industries that leverage Drive-In racks include:

- Food & Beverage – bulk ingredients & packaged goods

- Cold Storage – maximizing space in freezer rooms

- Manufacturing – raw materials & WIP buffers

- Distribution Centers – staging high-volume SKUs

- Retail Back-Stock – dense storage for fast movers

- Agriculture – harvested produce & packaging supplies

Suitability for Perishable Goods (LIFO Considerations)

While Drive-In racks are not ideal for very short-dated items, they can work when:

- Products have sufficiently long shelf life

- Strict date tracking is enforced

- High-volume SKUs cycle quickly through inventory

Robust inventory control is essential to minimize waste.

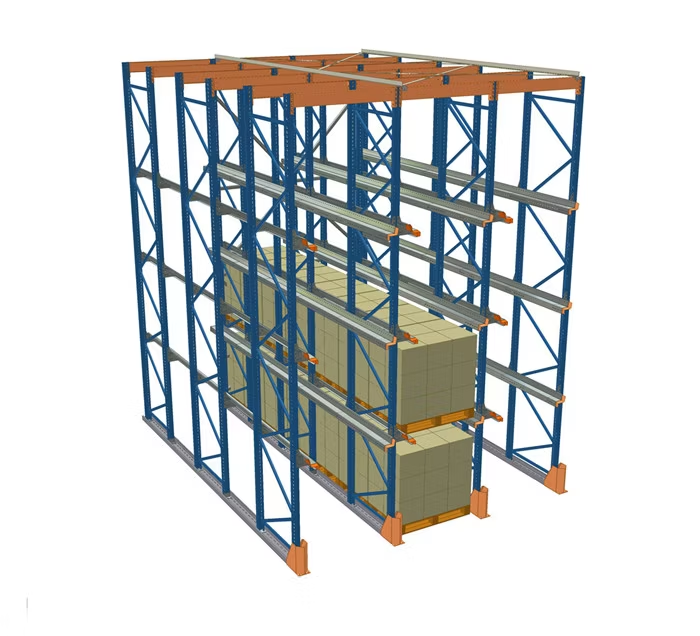

How Drive-In Pallet Rack Systems Work

Drive-In pallet rack systems operate on a unique principle that allows forklifts to drive directly into the storage lanes to deposit or retrieve pallets. These systems are ideal for storing multiple pallets of the same SKU and are commonly used where LIFO inventory control is suitable. Deep-lane configuration and minimal aisle requirements significantly increase storage density, making them a great solution for high-volume, low-SKU operations.

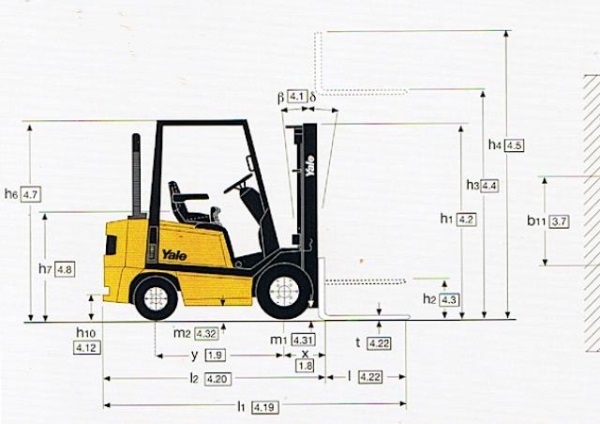

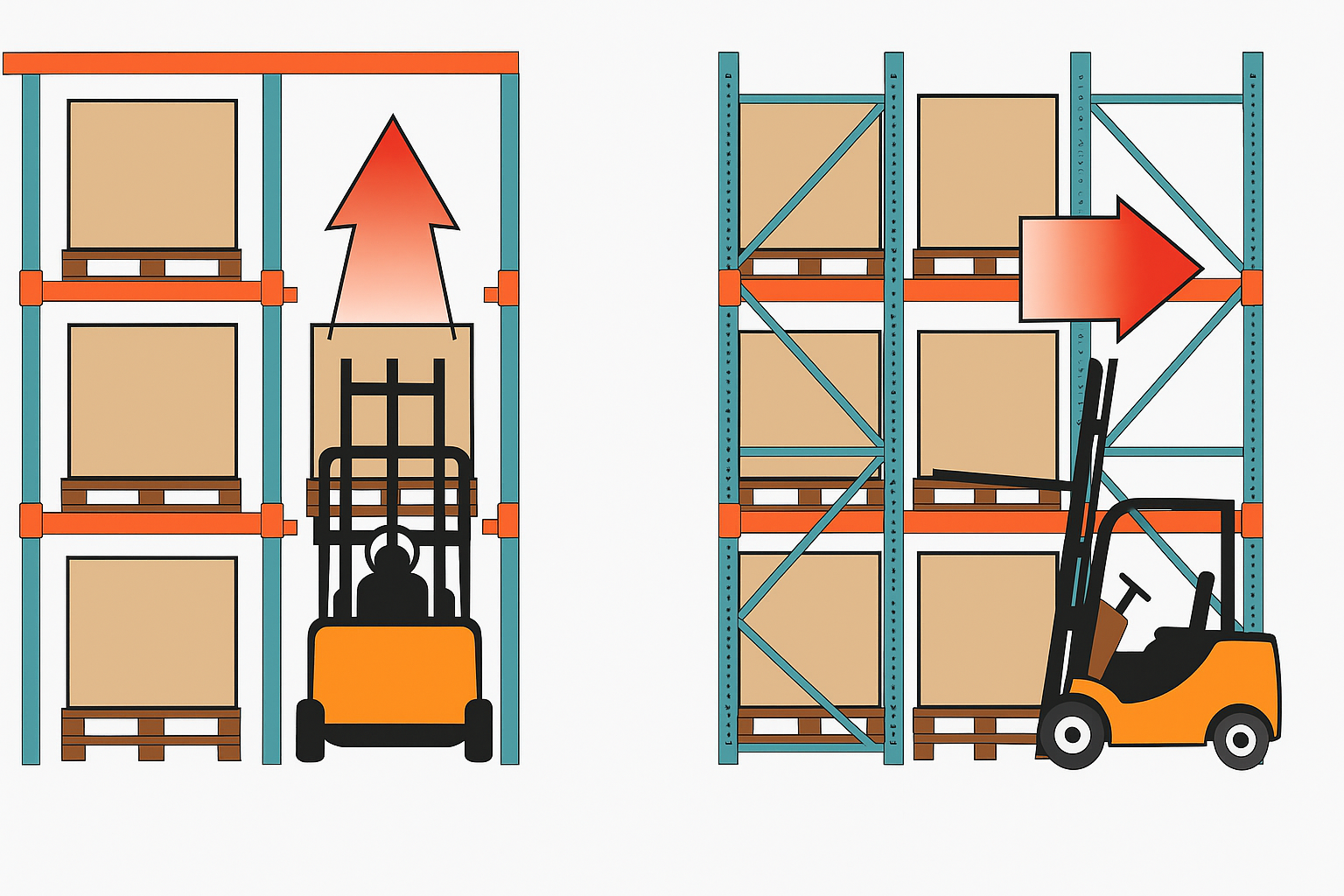

Forklift Loading into Lanes

In a drive-in system, forklifts enter each storage lane and travel down the aisle between rails to place or retrieve pallets. The pallet rails act as guidance tracks to ensure precise loading and unloading, which reduces product damage. This method eliminates the need for multiple aisles and allows forklifts to stack pallets deep within the racking system, enhancing both space efficiency and storage density.

LIFO Inventory Flow

Drive-in racking follows the Last-In, First-Out (LIFO) method where the most recently stored pallet is the first to be retrieved. This makes it ideal for products that are not time-sensitive and simplifies the loading/unloading sequence within each lane.

Deep-Lane Storage Explained

Deep-lane storage allows several pallets to be stored one behind the other in a single lane. This design minimizes the number of aisles needed and maximizes floor space, making it perfect for high-density inventory zones.

System Layout Visualization

A well-designed drive-in rack layout incorporates clear entry and exit points, rail guidance, and optimal bay depth per product type. Visualization aids operators in safe and efficient movement inside racking lanes.

💡 Pro Tip: To ensure smooth operation in drive-in racks, always train forklift operators on bay entry angles and lane depth limits. Routine inspection of rails and backstops ensures safety and minimizes damage risks.

Design and Installation Considerations

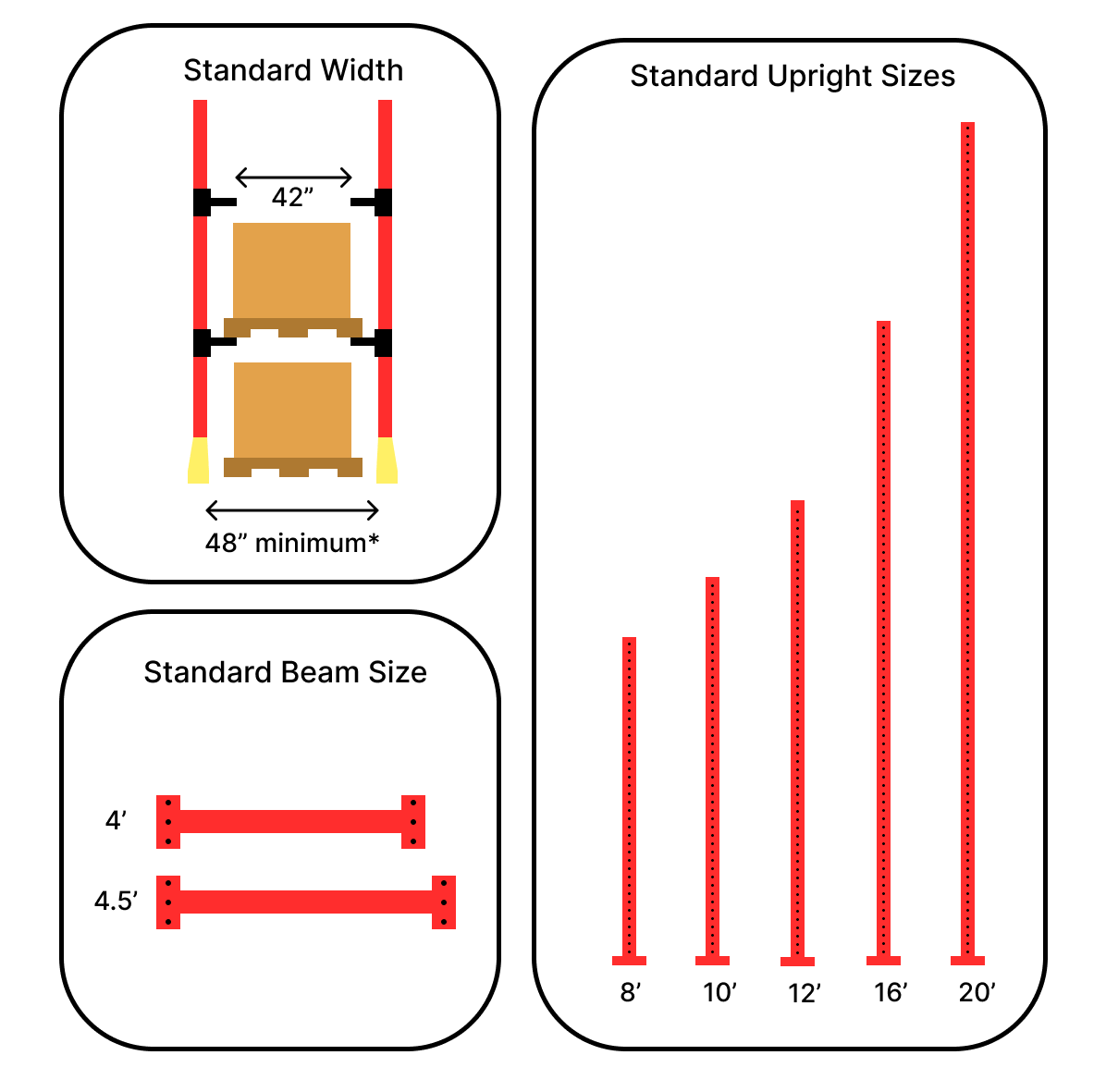

Proper design and installation are critical for the safety and efficiency of a drive-in pallet rack system. This involves careful planning of the warehouse layout, consideration of structural elements, customization based on specific needs, and adherence to safety regulations. Let's explore some key aspects to consider during the design and installation process.

Layout Planning

Strategic layout planning is essential. Consider entry and exit points for forklifts to ensure smooth traffic flow. Determine appropriate bay depths based on the number of pallets per SKU. Optimize aisle widths to balance accessibility and storage density.

Anchoring, Spacing, and Clearances

Proper floor anchoring is crucial for the stability and safety of the racking system. Maintain correct rack spacing to allow for safe forklift operation and prevent collisions. Ensure adequate clearances, both horizontally and vertically, for the specific forklifts being used.

Customization for Specific Needs

Drive-in racks can be customized to accommodate various product types, sizes, and weights. Adjustments can be made to bay height, depth, and overall system dimensions to optimize storage based on your specific inventory and warehouse size.

Coordination with Forklift Specs

The design must align with the specifications of the forklifts that will be used in the system. Consider the turning radius required for maneuvering within aisles, the maximum vertical reach needed for accessing top pallets, and the overall dimensions of the forklift to ensure safe and efficient operation.

Safety and Compliance

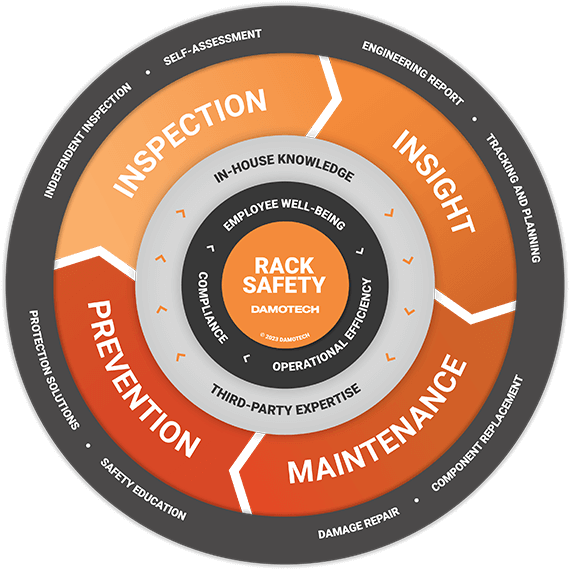

Adherence to safety guidelines is paramount. Ensure the design and installation comply with relevant regulations, such as OSHA standards. Consider seismic zones and implement appropriate structural reinforcements if necessary to protect against earthquakes. Regular inspections and maintenance are also crucial for ongoing safety.

Safety First: Operating Your Drive-In Racks Safely

Ensuring the safety of personnel and preventing damage to goods and equipment are paramount when operating drive-in racking systems. These guidelines outline crucial safety practices that all operators must adhere to for a secure and efficient warehouse environment.

Trained Operators Only

Ensure that only properly trained and certified forklift operators are permitted to operate within the drive-in rack system.

Adhere to Load Limits

Never exceed the specified load capacity for each pallet position and the overall rack structure to prevent structural failure.

Proper Pallet Placement

Ensure pallets are placed squarely and securely onto the support rails, avoiding pushing them too far back

Maintain Clear Lanes

Keep the drive-in lanes free from any obstructions, including loose pallets, debris, or equipment, to ensure safe movement.

Controlled Forklift Entry and Exit

Forklift operators must enter and exit the lanes slowly and carefully, keeping the forklift aligned with the guide rails to avoid damage.k.

Regular Inspection for Damage

Before each use, visually inspect the racking system for any signs of damage and report any issues immediately.

Communicate and Follow Site-Specific Rules

Establish, communicate, and ensure adherence to all site-specific safety rules and procedures for the drive-in rack system.

💡 Pro Tip: To ensure smooth operation in drive-in racks, always train forklift operators on bay entry angles and lane depth limits. Routine inspection of rails and backstops ensures safety and minimizes damage risks.

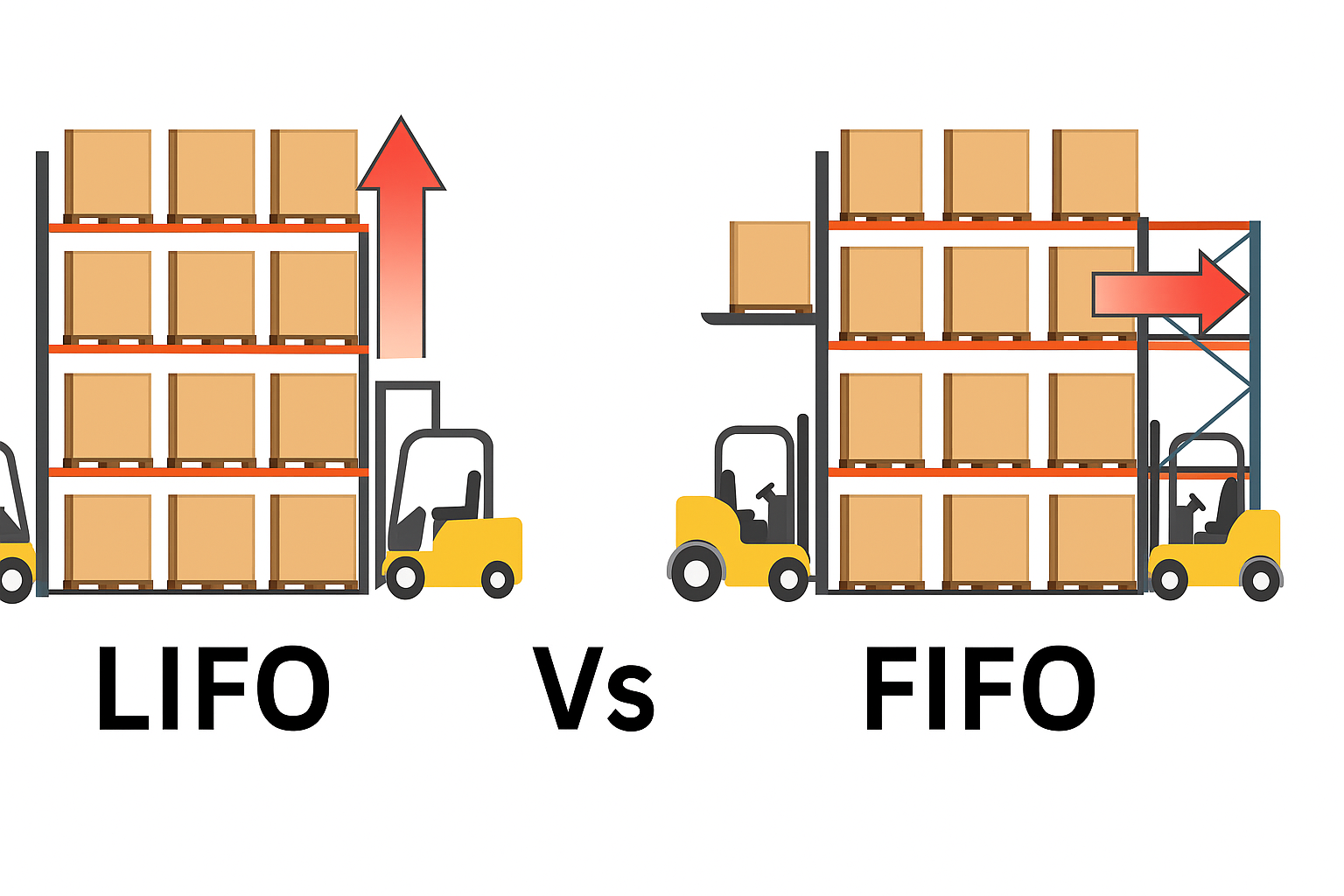

Drive-In Racks vs Drive-Through Racks: A Comprehensive Comparison

Drive-In and Drive-Through racking systems are both popular solutions for warehouse storage, each offering unique advantages for different operational needs. In this section, we compare these two systems to help you understand their differences and determine which one is more suited to your business's needs. We'll explore the key features, benefits, and ideal use cases for both, focusing on their impact on space optimization, inventory management, and operational efficiency.

Drive-In Racks (LIFO)

Drive-In racks are designed to store large quantities of the same SKU using the LIFO method. They are highly efficient for bulk storage where quick access to recent stock is not a priority. These racks offer high-density storage by allowing forklifts to drive directly into the racking system, optimizing floor space.

Drive-Through Racks (FIFO)

Drive-Through racks, on the other hand, utilize the FIFO method, making them ideal for perishable goods or inventory that requires frequent rotation. Forklifts can access pallets from both sides of the rack, allowing for easier loading and unloading, which increases operational flexibility.

Drive-In vs Drive-Through: Storage Efficiency

Drive-In Racks are more space-efficient as they minimize aisle space and store pallets deeply within the system. However, they only allow access from one side, which may limit accessibility. On the other hand, Drive-Through Racks offer access from both sides, making them more flexible but slightly less space-efficient due to the need for two entry points.

Inventory Flow: LIFO vs FIFO

Drive-In Racks utilize the LIFO (Last-In, First-Out) method, meaning the most recently stored items are the first to be retrieved. This is ideal for products that are not time-sensitive and simplifies the loading/unloading sequence within each lane. Drive-Through Racks use FIFO (First-In, First-Out), ensuring that the oldest products are retrieved first, which is perfect for perishable goods.

Space Optimization with Drive-In vs Drive-Through

Drive-In Racks are better for maximizing space in warehouses with fewer SKUs, as they store products in deep lanes with minimal aisles. Drive-Through Racks provide more accessibility but require more space due to the dual entry/exit points, which can slightly reduce their overall storage density.

Ideal Use Cases for Drive-In and Drive-Through Racks

Drive-In Racks are best for warehouses that need to store large quantities of the same SKU, such as seasonal products or bulk inventory. Drive-Through Racks, on the other hand, are better for industries that require stock rotation, like food and beverage or pharmaceuticals, where FIFO is critical.

| Feature | Drive-In Racks | Drive-Through Racks |

|---|---|---|

| Storage Method | Last-In, First-Out (LIFO) | First-In, First-Out (FIFO) |

| Access Points | Access from one side only | Access from both sides |

| Ideal for | Large quantities of the same SKU | Perishable goods, fast inventory rotation |

| Space Efficiency | High density, fewer aisles needed | Less space-efficient, requires more aisles |

| Best for | Bulk storage, non-time-sensitive goods | Time-sensitive goods like food, pharmaceuticals |

| Inventory Flow | LIFO method, most recent items retrieved first | FIFO method, oldest items retrieved first |

💡 Pro Tip: When considering Drive-In or Drive-Through racks, take into account your inventory management system. If you work with perishable goods, Drive-Through may be a better option. However, for long shelf-life goods, Drive-In racks can save more space and be more cost-effective.