Carton Flow Racking

Streamline Order Picking with Gravity-Fed Shelving

Smart, Sloped, and Streamlined: Carton Flow Racks That Keep Inventory Moving

Carton flow racking systems offer a dynamic storage solution for fast-moving inventory, enabling first-in, first-out (FIFO) inventory rotation and improving picking efficiency. Perfect for e-commerce, retail, food, and pharmaceutical operations, these racks utilize gravity-fed lanes that keep cartons continuously available at the picking face. Discover why businesses choose carton flow racks to enhance warehouse throughput, minimize replenishment time, and save valuable space. Learn more about our pallet racking solutions for comprehensive storage options.

Why Choose Carton Flow Racking?

- ✔ High Pick Efficiency: Reduce picking errors and improve speed with ergonomic carton access.

- ✔ FIFO Inventory Management: Automatic product rotation ensures older stock is used first.

- ✔ Space Optimization: Sloped lanes eliminate wasted shelf space and support higher density storage.

Carton Flow Systems: Streamlined Efficiency

Carton flow systems are dynamic storage solutions designed for first-in, first-out (FIFO) inventory management. Utilizing gravity, these systems allow cartons to glide smoothly on inclined tracks, ensuring easy access and efficient stock rotation. Ideal for high-volume order fulfillment, carton flow racks significantly reduce picking times and optimize warehouse space, making them a cornerstone of modern logistics.

- Key Advantages

- Applications

- Design Insights

Key Advantages

- ✅ Improves picking accuracy and speed, crucial for fast-paced environments.

- ✅ Optimizes space utilization by creating dense storage lanes and reducing aisle space.

- ✅ Ensures automatic FIFO stock rotation, minimizing spoilage and obsolescence.

- ✅ Reduces labor costs associated with travel and searching for items.

Applications

- 📦 Ideal for e-commerce fulfillment centers managing a high volume of SKUs.

- 📦 Suitable for distribution centers requiring efficient order processing.

- 📦 Used in pharmaceutical warehouses for managing date-sensitive inventory.

- 📦 Applicable in retail backrooms for streamlined restocking processes.

Design Insights

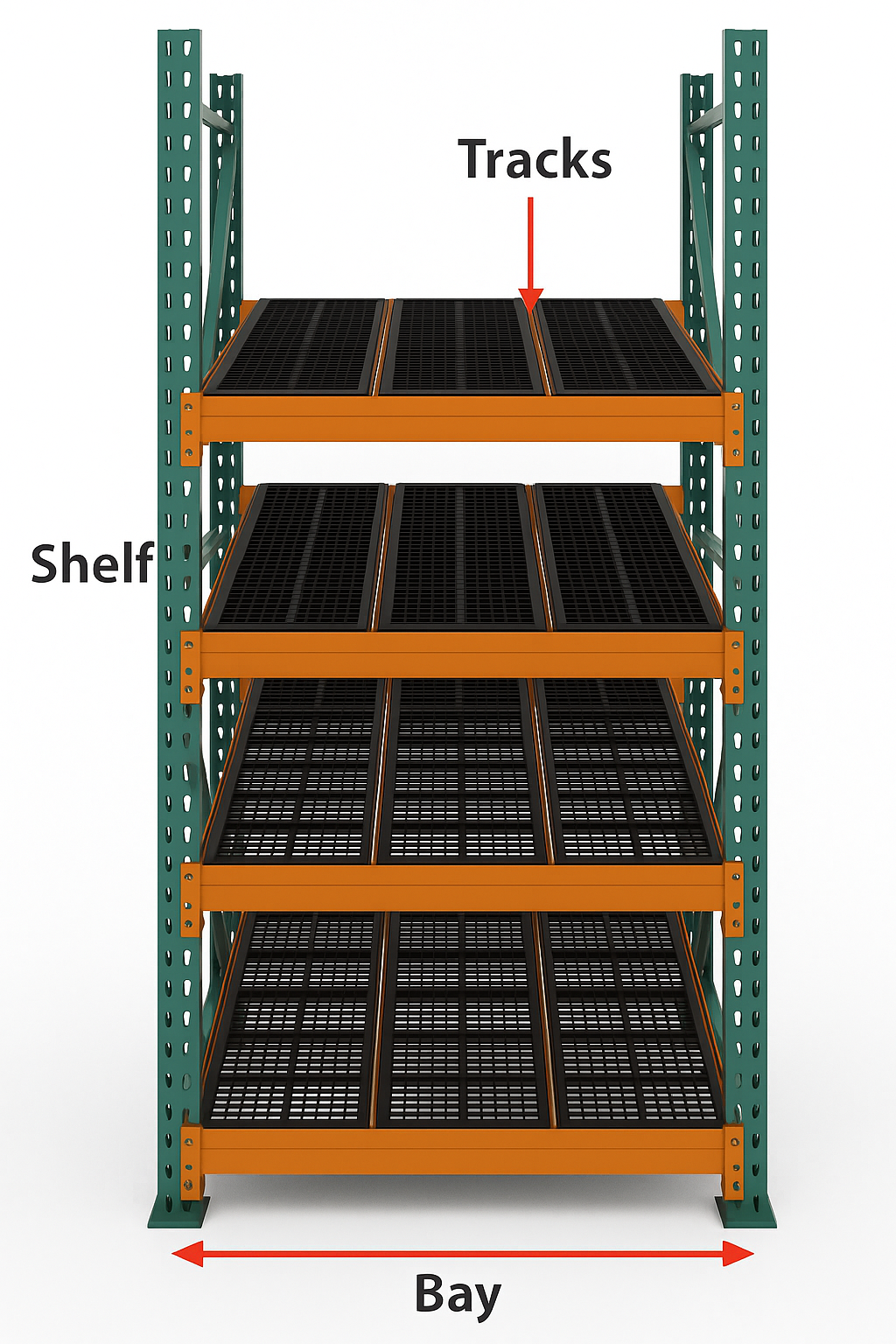

Effective carton flow system design considers factors like carton dimensions, weight, and flow rate. The angle of the tracks is crucial for smooth movement, typically ranging from 3 to 5 degrees. Lane dividers ensure proper product separation, while different track options like rollers or wheel beds can be selected based on the carton base. Integration with pick modules and other material handling equipment further enhances efficiency.

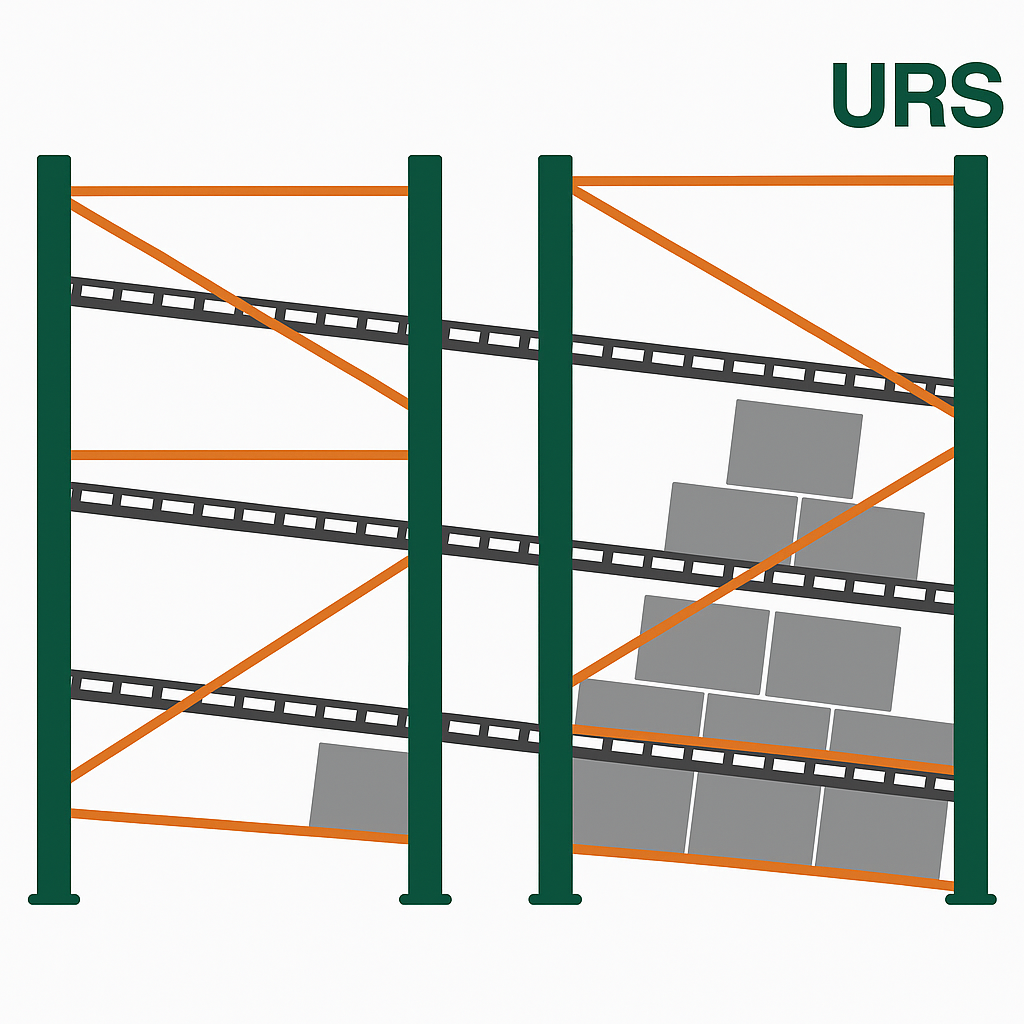

Understanding Carton Flow Rack Systems

Discover how carton flow rack systems utilize gravity and a smart design for efficient, first-in, first-out (FIFO) inventory management, setting them apart from traditional static shelving.

Gravity-Powered Movement

Inclined shelves with rollers or wheels allow cartons to glide smoothly towards the picking face using gravity.

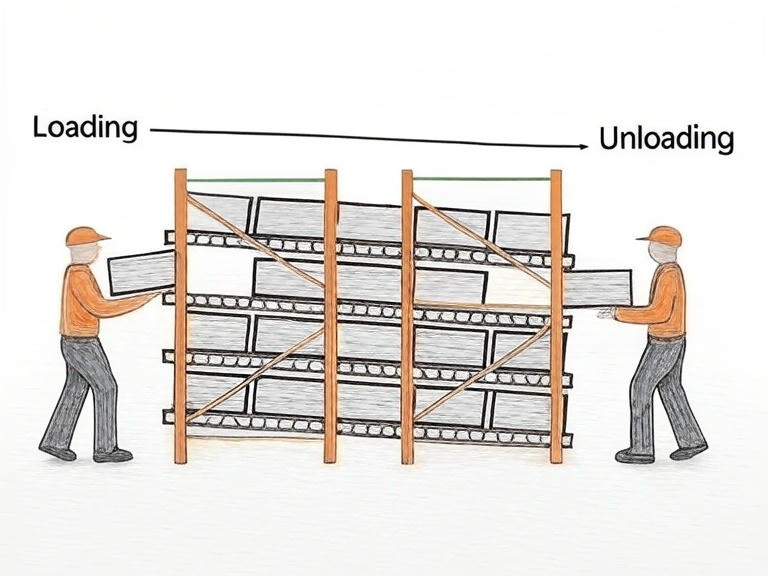

Rear Loading System

Cartons are loaded from the back of the rack, initiating the gravity-driven flow towards the front.

Controlled Glide

Rollers and wheels minimize friction, ensuring a consistent and gentle movement of cartons.

Automatic Replenishment

Picking a carton triggers the next one to automatically slide forward, keeping the picking face full.

First-In, First-Out (FIFO)

Loading from the rear and picking from the front inherently ensures that the oldest stock is used first.

Reduced Spoilage & Obsolescence

FIFO minimizes the risk of products expiring or becoming outdated due to prolonged storage.

Optimized Space

Compared to static shelving, carton flow racks allow for denser storage and reduced aisle space.

Enhanced Picking Efficiency

The continuous flow and readily available stock at the picking face significantly speed up order fulfillment.

Maximize Efficiency with Advanced Carton Flow Rack Systems

Unlock the full potential of your warehouse with our state-of-the-art carton flow rack systems. Designed for dynamic inventory management, these solutions utilize gravity to ensure a smooth, first-in, first-out (FIFO) process, optimizing space and accelerating order fulfillment. Discover the key components, design considerations, and diverse applications that make carton flow racks a smart investment for modern logistics.

- System Components

- Design & Installation

- Industry Applications

Key Components & Configuration Options for Optimal Flow

Our carton flow systems are built with precision-engineered components to ensure reliable and efficient operation:

- Types of Roller Tracks or Wheel Beds: Choose from full roller lanes for uniform carton bases or divided wheel beds for varying sizes, optimizing carton glide.

- Adjustable Frames: Robust uprights with adjustable levels to accommodate different carton heights and maximize vertical space utilization.

- Tilt Trays: Optional tilt trays at the picking end improve ergonomics and provide easier access to items within the cartons.

- Lane Guides: Ensure smooth and straight carton flow, preventing jams and maintaining lane integrity for consistent throughput.

- Load/Unload Ends: Specifically designed entry and exit points for safe and efficient loading from the rear and picking from the front.

- Entry Guides: Facilitate proper carton alignment during loading, minimizing damage and ensuring smooth entry into the flow lanes.

Critical Design & Installation Considerations for Performance

Proper design and installation are paramount for the efficiency and longevity of your carton flow system:

- Slope Angles and Shelf Depth: Determining the optimal incline (typically 3-5°) and shelf depth based on carton size, weight, and desired flow speed.

- Weight Capacity Planning: Engineering the system to handle the maximum anticipated load per lane, ensuring safety and preventing structural failure.

- Compatibility with Pallet Racks: Seamless integration with existing pallet racking systems to create hybrid storage solutions for diverse inventory needs.

- Seismic Considerations: Designing and anchoring systems to withstand seismic activity in earthquake-prone regions, ensuring workplace safety.

- Ergonomic Picking Heights: Configuring shelf levels to optimize picking comfort and efficiency, reducing strain on warehouse personnel.

Versatile Industry Applications for Streamlined Operations

Carton flow rack systems provide significant advantages across a wide range of industries:

- Warehousing & Logistics: Optimizing storage density and pick rates in distribution centers and general warehousing environments.

- E-commerce & Retail Fulfillment: Accelerating order processing and reducing picking errors for online and brick-and-mortar retailers.

- Food & Beverage: Facilitating FIFO for perishable goods, minimizing waste and ensuring product freshness throughout the supply chain.

- Pharmaceuticals: Maintaining strict inventory control and traceability for sensitive and date-coded medications.

- Automotive Parts: Efficiently storing and retrieving a high volume of smaller parts, improving organization in automotive warehouses.

- Manufacturing: Streamlining the flow of components and finished goods within production facilities, supporting lean manufacturing principles.

Quantifying Efficiency & Return on Investment with Carton Flow Racks

Investing in carton flow systems translates to significant improvements in operational efficiency and a strong return on your investment. Let's look at the key metrics:

Picking Speed Improvement

Carton flow racks significantly reduce picking time by presenting items directly at the picking face, eliminating search times and travel within aisles.

Labor Charges Savings

The streamlined flow and reduced picking distances lead to lower labor requirements for order fulfillment and restocking processes.

Reduced Restocking Times

Replenishing stock from the rear without interrupting picking operations minimizes downtime and accelerates the restocking process.

Aisle Congestion Reduction

The compact design and dedicated flow lanes decrease aisle congestion, improving forklift maneuverability and overall warehouse safety.

Impact on Picking Time

(Lower bar indicates faster picking time)

Return on Investment Timeline (Typical)

(Carton flow racks often show a faster and more direct ROI due to efficiency gains)

These metrics highlight the tangible benefits of implementing carton flow rack systems, leading to significant cost savings and a rapid return on investment through enhanced operational efficiency.

Exploring Carton Flow Rack Efficiency, Safety, and Customization

Learn how carton flow rack systems compare to other picking methods, understand crucial safety and maintenance practices, and discover customization options to optimize your warehouse.

Carton Flow vs. Static Shelving

Understand the key differences between carton flow racks and traditional static shelving. Discover how gravity-fed systems enhance picking efficiency and optimize warehouse space compared to fixed shelves.

Carton Flow vs. Pallet Flow

Explore the differences between carton flow for lightweight cartons and pallet flow racks for full loads. Know when each system is ideal based on SKU size and handling requirements.

Carton Flow vs. Push-Back Racks

Compare FIFO-based carton flow systems with LIFO push-back racks for cartons. Evaluate which system offers better throughput and inventory control for your operation.

Carton Flow Rack Safety Practices

Follow essential safety guidelines like weight limits, proper loading, and item containment to prevent accidents and maintain a secure warehouse environment.

Load Handling & Maintenance

Ensure system longevity by inspecting rollers, aligning tracks, and cleaning lanes regularly. Prevent downtime with proactive maintenance practices.

Customization: Dividers, Labels & Lane Stops

- Separate SKUs clearly using vertical dividers

- Use label holders for faster identification

- Install lane stops to prevent product overrun

Flexibility: Width, Depth & Scalability

- Adjust depth and width for diverse carton sizes

- Add modular lanes as your inventory grows

Frequently Asked Questions About Carton Flow Racking

🔄 What is the difference between a Carton Flow Rack and a Pallet Flow Rack?

Carton flow racks handle lighter items like boxes or bins using smaller lanes and wheels, while pallet flow racks are built for heavy, palletized goods and use full-width rollers. Both operate using gravity but serve different storage purposes.

🧲 Is a Gravity Flow Rack the same as a Carton Flow Rack?

Yes, a carton flow rack is a type of gravity flow system designed for smaller, hand-picked items. The term "gravity flow rack" is broader and also includes pallet flow racks.

📦 What is a carton flow rack system?

A carton flow rack uses gravity to move cartons from loading to picking face using rollers or wheel beds, allowing FIFO rotation and faster order picking.

⚙️ How does a carton flow rack work?

Cartons are placed on inclined tracks, and gravity moves them forward to the pick face. As one is removed, the next automatically slides into position.

✅ What are the benefits of carton flow racks?

They improve picking speed, reduce labor, maximize space, and support FIFO inventory—ideal for high-volume SKU and split-case operations.

🏬 Where are carton flow racks used?

They're used in e-commerce warehouses, retail fulfillment centers, food and beverage storage, pharmaceuticals, and automotive parts distribution.

🔩 Are carton flow racks compatible with pallet racks?

Yes. Most carton flow beds can be installed within standard pallet rack frames, creating hybrid storage for both cartons and pallets.

🛠️ Can the system be customized?

Absolutely. You can customize lane widths, use dividers, add tilt trays, label holders, and more to meet your exact picking and storage needs.

❄️ Are carton flow racks suitable for cold storage?

Yes. Many systems are made with galvanized or corrosion-resistant materials, making them ideal for cold or freezer environments. Check our flammable storage cabinets for specialized storage needs.