Double-Deep Pallet Racking

Increase Storage Capacity with Two-Pallet-Deep Efficiency

Double-Deep Pallet Rack System Highlights

Double-Deep Pallet Racks provide 2x storage density compared to selective racks by storing pallets two-deep, while still maintaining good accessibility with specialized forklifts. Perfect for operations needing more space without full drive-in commitment.

- Doubles storage capacity compared to selective racks

- Maintains better accessibility than drive-in systems

- Requires specialized reach trucks or forklifts

- Ideal for medium-turnover inventory with 2-4 SKUs per lane

- Perfect for distribution centers and bulk storage

How Double-Deep Pallet Racking Works

Double-deep pallet racking is a high-density storage solution designed to optimize warehouse space by storing two pallets deep per position. It operates on a Last-In, First-Out (LIFO) basis, making it ideal for items with lower rotation or bulk storage needs. By doubling pallet depth, this system reduces aisle space requirements while maintaining accessibility using deep-reach forklifts.

1. Dual-Pallet Depth

Pallets are stored two deep in each bay, doubling capacity without increasing rack footprint.

2. LIFO Access

Operates on a Last-In, First-Out flow ideal for bulk storage and non-perishable goods.

3. Space Optimization

Fewer aisles and higher density storage increase warehouse utilization and reduce travel time.

4. Deep-Reach Forklift Use

Requires a specialized deep-reach forklift to access rear pallets safely and efficiently.

5. Ideal for Bulk SKU

Perfect for storing large quantities of the same SKU in cold storage, food, or beverage warehouses.

Why Choose Double-Deep Pallet Rack?

The Double-Deep Pallet Rack system is a space-saving storage solution that allows pallets to be stored two-deep, effectively doubling your storage capacity per aisle. This high-density configuration is ideal for bulk inventory, low-turnover items, and operations using deep-reach forklifts. By reducing aisle count and increasing SKU storage per row, businesses can achieve optimal warehouse efficiency.

Key Advantages of Double-Deep Racking

- Maximized Storage Space: Reduces aisle space by doubling the pallet depth.

- Cost-Efficient: Lowers cost per pallet position for medium-turnover inventory.

- Versatile Compatibility: Works with deep-reach forklifts and standard pallet sizes.

- Enhanced Inventory Control: Perfect for storing similar SKUs in larger quantities.

Is Double-Deep Pallet Rack Right for You?

If your warehouse prioritizes storage density over direct access, the Double-Deep Pallet Racking system offers the perfect balance between cost, capacity, and performance. It is widely used in distribution centers, cold storage facilities, and manufacturing warehouses. Check our Pallet Rack Buying Guide for more details.

Key Benefits of Double-Deep Pallet Racking Systems

Double-deep pallet racking offers high-density storage without compromising selectivity. Perfect for medium-turnover products, this system optimizes space and reduces aisle count for improved productivity.

High Storage Density

Store two pallets deep per side, doubling your SKU storage in the same footprint as selective racks.

Reduced Aisle Space

Fewer aisles are needed, increasing warehouse storage capacity and operational efficiency.

Lower Equipment Costs

Standard forklifts with pantograph or deep reach can access double rows—no major equipment upgrades needed.

Ideal for Medium-Turnover SKUs

Suited for products that don’t require frequent picking but still need organized, accessible storage.

Flexible Layout Options

Easily integrates into existing layouts and scalable to accommodate changing inventory demands.

Cost-Efficient Expansion

Expand storage capacity without high capital investment—ideal for growing distribution hubs.

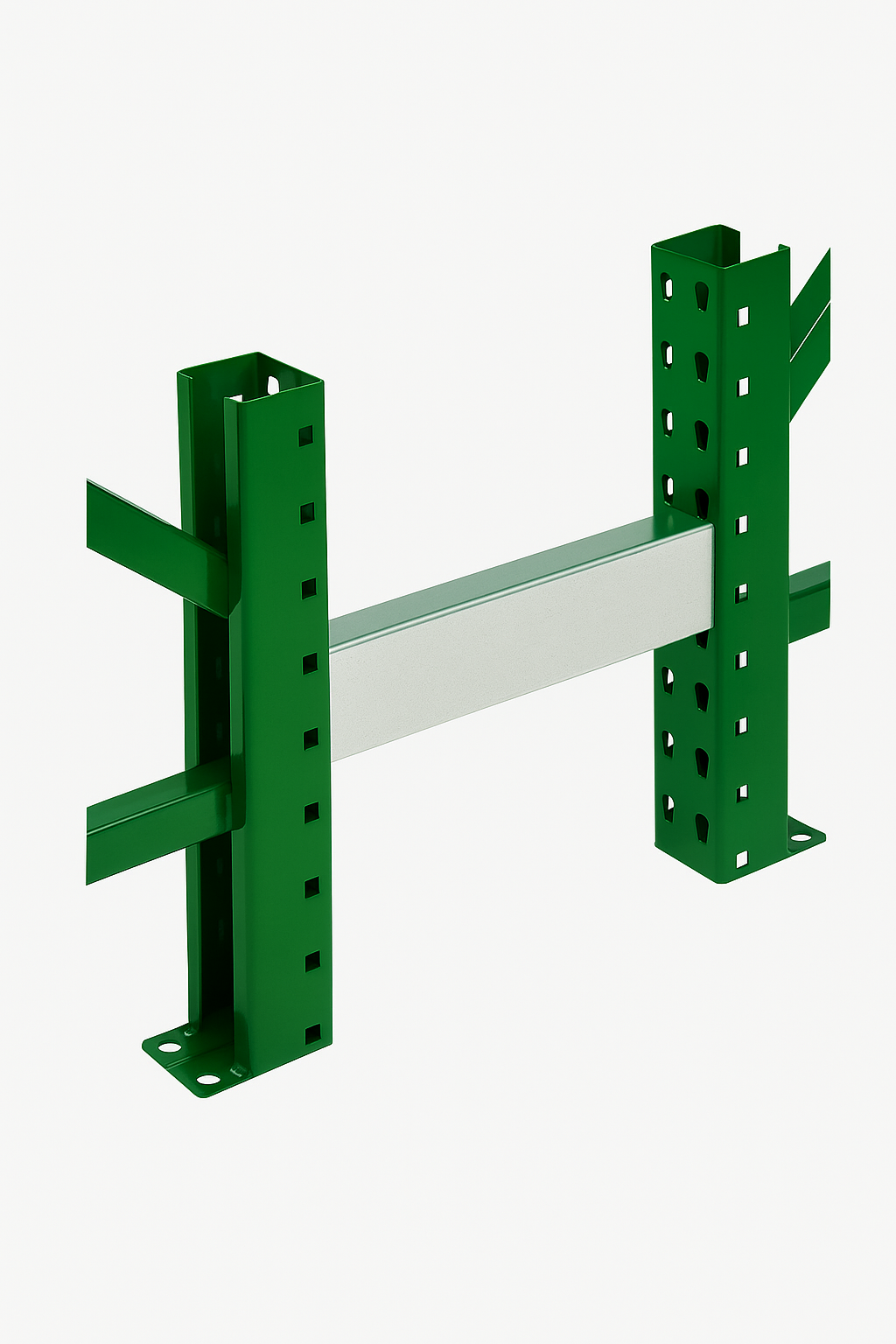

Essential Components of a Double-Deep Pallet Racking System

A Double-Deep Pallet Rack system is designed for high-density storage while maintaining efficient access. Below are the key structural components that ensure its performance, safety, and adaptability in modern warehouses.

Upright Frames

Provide vertical support and determine rack height and configuration.

Load Beams

Hold pallet loads and connect uprights for structural stability.

Row Spacers

Maintain consistent spacing between back-to-back racks for safe alignment.

Double-Reach Forklifts

Specialized forklifts used to access the rear pallet in double-deep systems.

Support Bars

Offer added safety and support for pallets, especially in rear positions.

Back Stops

Prevent pallets from being pushed too far and falling from the rear side.

Double-Deep Pallet Racking Applications by Industry

Retail & Wholesale

Ideal for storing fast-moving SKUs in bulk, while keeping aisles to a minimum for higher space use.

Distribution Centers

Supports fast order fulfillment with high pallet turnover and optimized picking efficiency.

Food & Beverage

Perfect for packaged or cold storage goods where maximizing cubic space is key.

Automotive

Stores large parts, tires, and components efficiently, especially in high-volume assembly zones.

Pharmaceuticals

Provides high-density storage for non-perishable medical supplies and controlled inventory.

Construction & Building Supplies

Handles heavy-duty materials like cement bags, plywood, and other bulk items securely.

Double-deep Pallet Rack System:

Design, Installation, and Safety Best Practices

To implement an efficient and long-lasting double-deep pallet racking system, it’s vital to address several design parameters, installation procedures, and safety practices that ensure structural stability and optimized forklift operations.

01

Forklift Reach Capability

Only use deep-reach forklifts designed to access the second pallet position safely and efficiently.

02

Load Weight Consistency

Maintain uniform pallet weights in each double-deep lane to reduce risk of leaning and beam stress.

03

Aisle Width Planning

Ensure enough aisle width for safe forklift maneuvering, typically 10–12 feet depending on truck type.

04

Pallet Quality

Use high-quality pallets without broken boards to ensure reliable stacking and reduce jams.

05

Frame & Beam Capacity

Design must match projected weight per level, including safety factors for dynamic load impact.

06

Safety Accessories

Install column protectors, row spacers, and safety pins to enhance protection and prevent collapse.

Frequently Asked Questions About Double-Deep Pallet Racking

🏗️ What is double-deep pallet racking?

A double-deep pallet rack stores two pallets deep per lane, increasing storage density while using fewer aisles.

🚜 Do I need special forklifts for double-deep racks?

Yes, reach trucks with extendable forks are required to access rear pallet positions in double-deep systems.

📦 Is it suitable for FIFO inventory?

No. Double-deep racking follows LIFO (Last-In, First-Out), so it's better for bulk storage and non-perishables.

🔧 Can I retrofit existing racks into double-deep?

Retrofitting is possible with proper structural upgrades, beam alignment, and fork reach adaptations.

🛡️ What are the safety considerations?

Ensure operator training, even pallet loads, and regular rack inspections to maintain workplace safety.

🏭 What industries benefit most?

Food & beverage, cold storage, automotive, and manufacturing industries commonly use double-deep racking.